PTB Serie

Schnell und effizient vorbehandeln – mit aeoon’s Vorbehandlungseinheit

Farbige Textilien müssen vorbehandelt werden, bevor sie in herkömmlichen DTG-Verfahren bedruckt werden können. Im Gegensatz zu anderen, auf dem internationalen Markt verfügbaren Drucksystemen, verwendet aeoon dafür eine externe Pretreatment-Maschine.

Diese Methode bietet große Vorteile gegenüber dem direkten Vorbehandeln im Drucker: Der Prozess ist nicht nur schneller und effizienter, sondern vermeidet auch Schäden im Inneren der Druckmaschine, die durch das interne Versprühen von Vorbehandlungsflüssigkeit entstehen. Zudem lässt sich die Menge und Position, in der die Flüssigkeit auf das Textil aufgetragen wird, exakt bestimmen. Durch das Bedrucken des bereits trockenen Textils, kann auch eine deutlich höhere Bildschärfe erreicht werden als mit der nass-auf-nass Methode. Feine Linien und Details lassen sich mühelos und klar drucken.

Mit der aeoon PTB-Einheit vorbehandelte Textilien lassen sich zudem bis zu einem Jahr lagern und eine Maschine kann für mehrere Drucker gleichzeitig vorbehandeln. Dadurch entsteht ein reibungsloser, effizienter und schneller Arbeitsablauf.

Vorteile:

- Individuelle Sprühbereiche mit bis zu 13 Düsen

- Laser erkennt vorzubehandelnde Bereiche automatisch

- Reinigungsfunktion der Düsen und des Förderbandes

- Speichern individueller Vorbehandlungs-Einstellungen

- Flüssigkeitswechsel einfach per Knopfdruck

- Große Sprühfläche: bis zu 1x3m

- Optional: Kann direkt an Trockner angeschlossen werden

Einfache Bedienung via Touchscreen. Häufig verwendete Einstellungen können einfach gespeichert werden.

Die PTB Serie verfügt über ein Reinigungsystem, das dafür sorgt, dass die Düsen und das Fließband sauber bleiben.

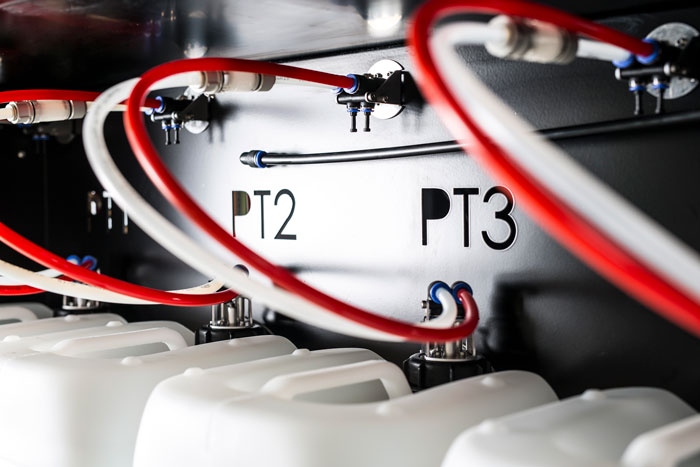

Die PTB Serie bietet Anschlüsse für 4 verschiedene Pretreatment Sorten. Der Wechsel zwischen den einzelnen Flüssigkeiten erfolgt per Knopfdruck.

aeoon Automation

aeoon Automation aeoon Support

aeoon Support aeoon Nachhaltigkeit

aeoon Nachhaltigkeit